The $42.6 Million Phase 2A Rehabilitation project at the City of Batavia's WWTF is nearing completion, several months ahead of schedule and with less than 0.5% in change orders. After completing off-site utility and roadway replacement, bike path realignment, replacement of the process flow disinfection system, and rehabilitation of the final clarifiers, wastewater was completely transferred over to the brand-new Headworks and Primary Clarifiers in October 2025. This project’s success is a result of the outstanding dedication and collaboration of the General Contractor IHC, the City of Batavia Public Works staff, and our Trotter project representatives. We sincerely thank everyone for making this achievement possible!

The City of Saint Charles has completed Sequence #1 of the Ohio Avenue and Kautz Road Raw Water Main Installation Project, advancing critical water infrastructure improvements. The work included installing a new raw water main between Well No. 8 and the future Well No. 14, along with other key infrastructure components and roadway restoration. Most of the water main was installed using horizontal directional drilling to minimize surface impacts and limit disruption, and hydrants were installed by open-cutting. Trotter and Associates supported the City by securing EPA funding, designing the water main alignment, assisting with the bidding process, and observing construction in cooperation with City staff.

Trotter and Associates, Inc. provided start-to-finish engineering services to the Village of Fox Lake for their 2025 Motor Fuel Tax (MFT) Roadway Improvement Project, delivering support from initial conceptual design through final construction closeout. The project rehabilitated over one mile of Village roads using a strategic mix of reconstruction and resurfacing techniques. The team’s expertise allowed the Village to make the most of its MFT funds while meeting critical infrastructure needs. By utilizing full-depth pavement reclamation with cement in conjunction with conventional milling and resurfacing operations, the Village successfully addressed underlying subgrade deficiencies in critical areas while extending roadway rehabilitation across multiple streets throughout the community, within the established project budget. Trotter and Associates, Inc.'s comprehensive approach ensured efficient project delivery, regulatory compliance, and optimal utilization of available funding resources for this essential infrastructure investment.

The Village of Algonquin’s Water Treatment Plants No. 1 and No. 2 Aerators and Roof Replacement project is nearing completion. With the new aerators operational, the Village will more effectively oxidize contaminants, enabling the facility to continue providing high-quality water to the community. The new aerators also enhanced the facilities' capabilities and minimized objectionable odors. WTP No. 1 is a vital facility and cannot be taken out of service. This required careful planning and communication among the team to ensure uninterrupted operations. Close coordination between the Village of Algonquin, Trotter and Associates, and Keno and Sons Construction Company enabled the project to be successfully sequenced and completed within budget.

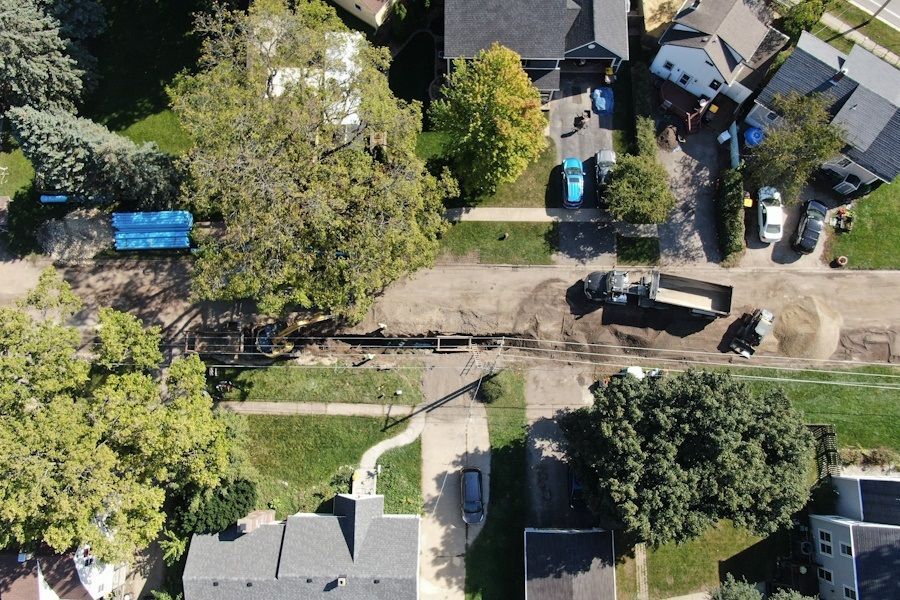

The City of Woodstock is continuing to enhance its aging infrastructure through its Gould Street Water Main Replacement project. Once complete, the project will have replaced and upsized a quarter mile of water main from 4” to 8”, which reinforces the system's operation and longevity. Various storm and sanitary sewer point repairs were also completed to ensure all underground improvements within the roadway were completed before resurfacing and reconstruction of the various roadways.

The Glenbard Wastewater Authority has hired Trotter and Associates, Inc. to move forward from the design phase to resident engineering services for the primary clarifier rehabilitation project. As part of these upgrades, the primary clarifiers, gravity thickeners, solids pumping system, and electrical and control systems will be replaced and upgraded due to aging infrastructure. The Authority has completed a 47 MGD bypass with six suction lift pumps and three overland force mains. This bypass allowed the primary clarifiers to be taken offline, enabling the installation of diversion structure gates that includes three new downward-opening weir gates and two new sluice gates. Over the following months, each clarifier will be taken out of service independently for complete removal and replacement with new stainless-steel mechanisms. The project team included Vissering Construction, Connelly Electric Co., Dahme Mechanical Industries, and Tri-R Systems, Inc. To learn more, follow TAI’s Current Projects at trotter-inc.com , or contact one of our team members.